Ferroalloy Furnaces

Our solution comprehensively covers the core stages of ferroalloy production, including tapping, processing, casting, and product crushing.

It provides complete sets of equipment and systems required for each stage, helping you achieve efficient and synchronized production.

Smelting and Tapping

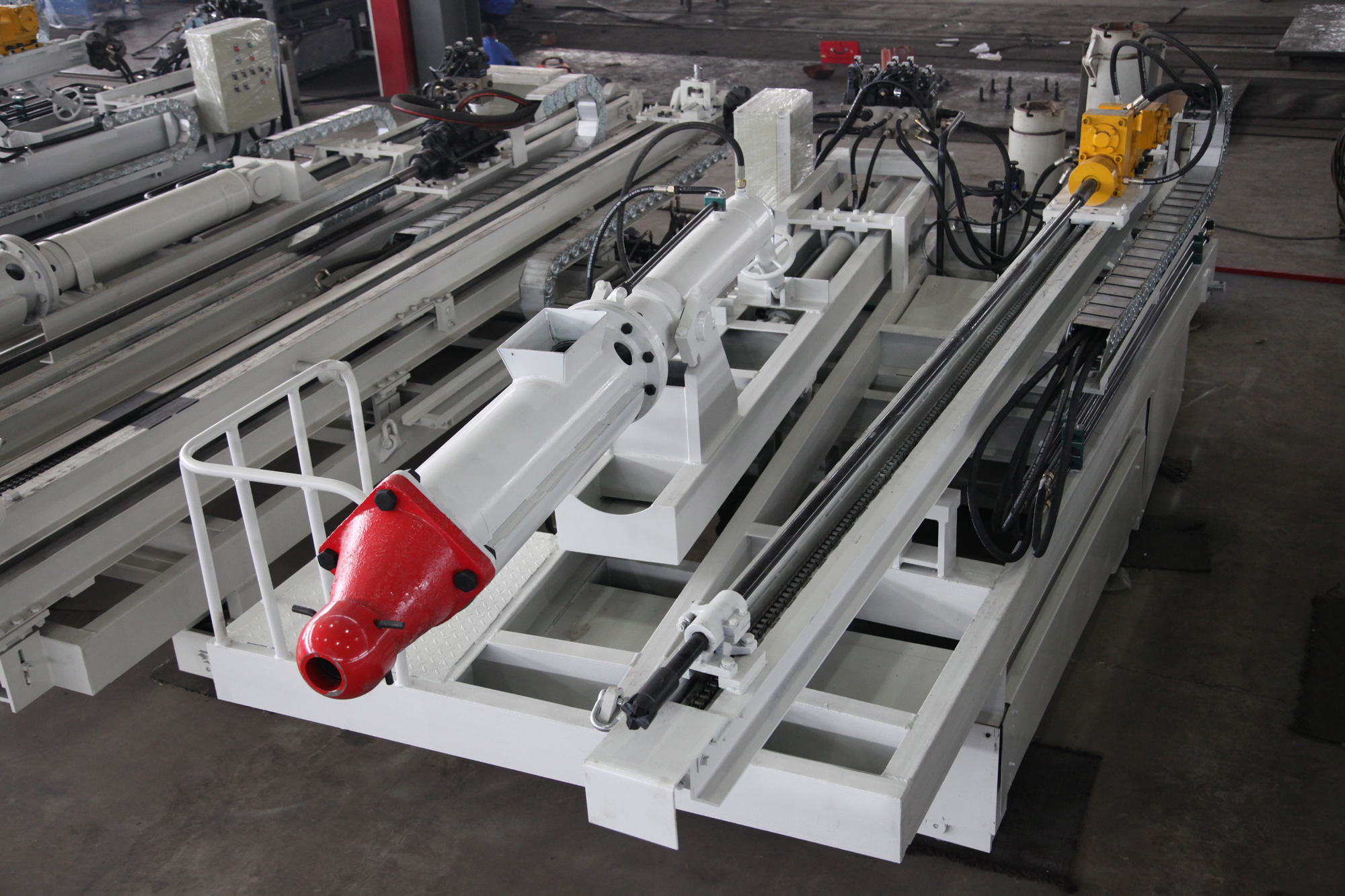

Mud gun and tapping drill – Type 1

Mud gun and tapping drill – Type 2

Mud gun and tapping drill – Type 3

Function, Power and Key Specifications

- Function: Drilling device, Mud gun, Poker device

- Power: Pneumatic/Hydraulic Rock Drill

380v

50-180L

65-100mm

1.6-2.5m

6300-80000KVA

3-5m

The above parameters are for reference; customization is available according to specific requirements.

Plant-wide Auxiliary Systems

The hydraulic power system is the keyto ensuring the operation of high-powermachinery.

It consists of a hydraulic power station,accumulator group, hydraulic controlvalve platform, and other components.

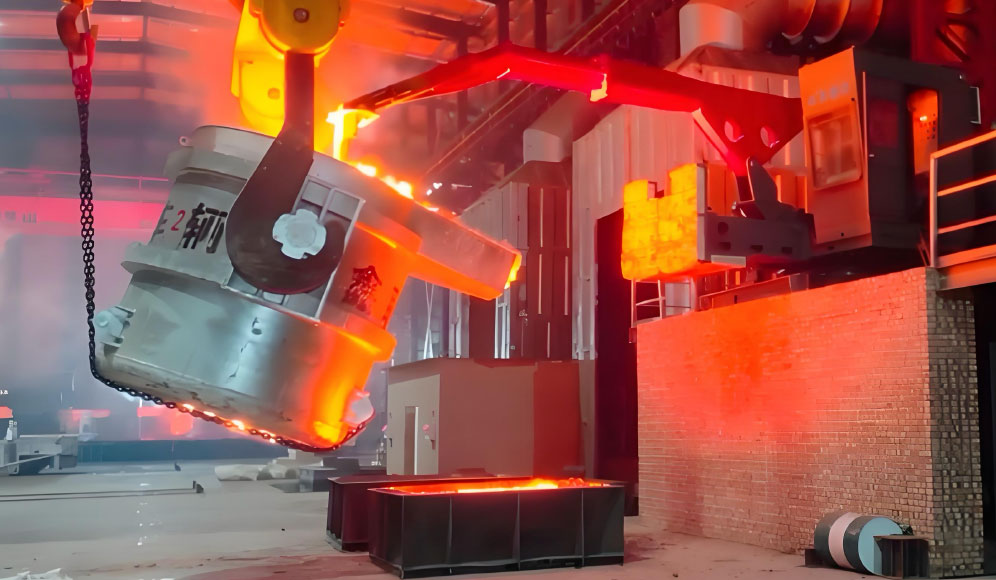

Hot Metal Transfer and Pretreatment

The Hydraulic-tilting transfer ladle system delivers isspecially designed for use when pouring molten ironduring steel ladle casting.

It adopts variable frequency speed control technologyto ensure that the molten steel flow rate remainsconstant at any tilt angle, with the outlet directionunchanged.

30°/min

45°/min

DG280-1800

16MPa

100T

115°

Hot Metal Transfer and Pretreatment

The slag skimmer is used to remove the floating slag from the molten iron ladle before pouring, improving the quality of the finished product.

4 m

1300 mm

0 ~ 100°

10000 N

Hot Metal Transfer and Pretreatment

The system utilizes a 36V low-voltage AC track power supply, where the traction vehicle collects electrical energy from the track. This energy is then boosted to 380V by the on-board device to drive the traction motor, enabling the traction vehicle to pull flat cars carrying loads of several hundred tons along the track. This technology replaces traditional steel cable traction methods and offers advantages such as high safety, strong reliability, and a high level of automation.

It is suitable for long-distance travel within factory workshops or between workshops, operation on curved and circular routes, as well as switching tracks, serving as a solution for material transportation.

Ladle Cleaner

Tundish Deslagging Robot is a fully hydraulic, wirelessly remote-controlled, tracked self-propelled robot. Its flexible mechanical arm, combined with tools such as hydraulic hammers, slag removal hammers, excavation buckets, hydraulic shears, and hydraulic grabs, enables it to perform various construction tasks. The equipment is powered by a diesel internal combustion engine. Featuring a compact design, easy mobility, and the ability to maneuver flexibly in confined spaces, it is particularly suitable for operation in limited areas.

Safe and convenient operation, significantly reducing manual labor intensity and enhancing operational safety.

Utilizes a tracked vehicle chassis, enabling mobility across multiple workstations for smooth and straightforward deslagging operations.

It is applicable in industries such as iron and steel, metallurgy, furnace dismantling, tundish/ladle cleaning, slag removal, trough clearing, construction, mining, excavation, scaling, and specialized sectors. When equipped with an imaging system, it enables remote control operations in high-risk environments.

Ready to take your project to the next level?

Trust our experienced team to provide customized solutions for your project. We’re available 24/7 to answer your questions. Contact us now to get started.