On September 23, the China Innovation and Entrepreneurship Advanced Manufacturing Industry National Final entered its tense and intense semifinal stage. At 7 AM, the competition organizing committee began preparing, and nearly 300 contestants from across the country arrived at the venue to wait and start the semifinal showdown. After a full day of fierce competition, 72 outstanding companies and 10 exceptional teams were selected.

The competition adhered to the principles of fairness, justice, and openness. During the opening ceremony on Monday night, a random grouping method was used to divide all contestants into 10 groups: 8 groups for companies and 2 groups for teams. Each group consisted of participants from different regions, with an even distribution of participants.

Semifinal Judges

Contestants during the competition

The semifinals officially began at 8 AM, unveiling its mysterious veil. The competition organizing committee specially invited 30 top venture capital representatives from across the country to serve as judges for the event. Each competition venue was staffed with 3 judges who evaluated the projects. The competition followed an “8+7” format, where contestants had 8 minutes to present their projects, followed by 7 minutes for questions from the judges. Each contestant was evaluated by 3 venture capital judges, and the scores were recorded to two decimal places as per the competition rules, with the average score being the final score. After the contestant and the judges took a photo with the scorecard and signed it, the contestant could leave, and the next contestant would continue. After brief questions from the judges, those who were impressed by a contestant could issue a D-day entrepreneurial guidance invitation card, enabling face-to-face communication and potential connections that could lead to funding opportunities.

While the semifinals were quite nervous, they were filled with confidence and passion when introducing their entrepreneurial projects to the judges. As expected, these outstanding contestants had been carefully selected from across the country and were well-prepared. Most of them could complete their PPT presentations within 8 minutes and answer the judges’ questions clearly.

The participating projects in the advanced manufacturing sector covered a wide range of industries, such as CNC machine tools, marine engineering equipment, aerospace equipment, aviation equipment, additive manufacturing, biomanufacturing, and micro-nano manufacturing. Overall, the judges generally noted that the number of entries had increased compared to the previous competition, and the quality had greatly improved. They expressed great optimism for the future development of China’s advanced manufacturing industry.

The organizing committee also selected 72 outstanding companies and 10 exceptional teams. The awards ceremony took place during the evening cocktail reception.

List of Outstanding Companies (Teams) in the Semifinals

| Category | Rating | Company/Team Name |

|---|---|---|

| Company 1 | Excellent | Hefei Abase Information Technology Co., Ltd. |

| Company 1 | Excellent | Zhejiang Flash Print 3D Technology Co., Ltd. |

| Company 1 | Excellent | Shandong Xinte Machinery Equipment Co., Ltd. |

| Company 1 | Excellent | Wuhan Lithium Xin Automation Technology Co., Ltd. |

| Company 1 | Excellent | Sheng Jie Feng Electronics (Xiamen) Co., Ltd. |

| Company 1 | Excellent | Yinson Electrical Systems (Shanghai) Co., Ltd. |

| Company 1 | Excellent | Tangshan Dongtang Electrical Equipment Co., Ltd. |

| Company 1 | Excellent | Tianjin Tianqi Mofeiyue Aviation Equipment Technology Co., Ltd. |

| Company 1 | Excellent | Tianjin Yuhang Runming Technology Development Co., Ltd. |

| Company 2 | Excellent | Nantong Lanpeng Information Technology Co., Ltd. |

| Company 2 | Excellent | Wuhan Acaris Optoelectronics & Automation Co., Ltd. |

| Company 2 | Excellent | Zhejiang Fengniao Vehicle Co., Ltd. |

| Company 2 | Excellent | Weihai New Beiyang Zhengqi Robotics Co., Ltd. |

| Company 2 | Excellent | Shenzhen Qianhai Zhilian Comma Technology Co., Ltd. |

| Company 2 | Excellent | Dongguan You Shida Machinery Technology Co., Ltd. |

| Company 2 | Excellent | Shanghai He Wu New Materials Technology Co., Ltd. |

| Company 2 | Excellent | Tianjin Tongguang Group Special Equipment Co., Ltd. |

| Company 2 | Excellent | Chongqing Litu Qingyan Lingchuang Measurement and Control Technology Co., Ltd. |

| Company 3 | Excellent | Sichuan Zigong Haichuan Industry Co., Ltd. |

| Company 3 | Excellent | Jiangsu Fengxin Stainless Steel Manufacturing Co., Ltd. |

| Company 3 | Excellent | Yancheng Sugo High-tech Machinery Co., Ltd. |

| Company 3 | Excellent | Huzhou Columbus Logistics Technology Co., Ltd. |

| Company 3 | Excellent | Jinan Yifei Automation Technology Co., Ltd. |

| Company 3 | Excellent | Changzhou Dasi Shicheng Electromechanical Technology Co., Ltd. |

| Company 3 | Excellent | Jilin Hanfeng Electrical Co., Ltd. |

| Company 3 | Excellent | Beijing Wuze Kun Technology Co., Ltd. |

| Company 3 | Excellent | Tianjin Chengli Aviation Technology Co., Ltd. |

| Company 4 | Excellent | Hangzhou Xundian Business Services Co., Ltd. |

| Company 4 | Excellent | Shenzhen Zhongke Sensor Technology Co., Ltd. |

| Company 4 | Excellent | Xinjiang ExtremeFly Agricultural Technology Co., Ltd. |

| Company 4 | Excellent | Xiamen Xiexuan Optoelectronics Co., Ltd. |

| Company 4 | Excellent | Guangdong Kekeda Intelligent Robot Co., Ltd. |

| Company 4 | Excellent | Shanghai Feigu Automation Technology Co., Ltd. |

| Company 4 | Excellent | Shandong Oryan Electrical Co., Ltd. |

| Company 4 | Excellent | Jinzhong Yuci Haiyang Hydraulic Co., Ltd. (the only one in Shanxi) |

| Company 4 | Excellent | Jiangsu Weiying Machinery Co., Ltd. |

| Company 5 | Excellent | Jiangsu United Transmission Equipment Co., Ltd. |

| Company 5 | Excellent | Fujian Hongyu Electronics Technology Co., Ltd. |

| Company 5 | Excellent | Taizhou Xianglong Container Technology Co., Ltd. |

| Company 5 | Excellent | Tianjin Beidi Safety Equipment Co., Ltd. |

| Company 5 | Excellent | Jiangsu Kuntai Machinery Co., Ltd. |

| Company 5 | Excellent | Tianjin Wenda Petroleum Drilling Engineering Equipment Co., Ltd. |

| Company 5 | Excellent | Xinjiang Tehan Industrial Equipment Co., Ltd. |

| Company 5 | Excellent | Shenzhen Yiparking Garage Technology Co., Ltd. |

| Company 5 | Excellent | Jintian Environmental Technology (Shanghai) Co., Ltd. |

| Company 6 | Excellent | Dalian Zongyi Technology Development Co., Ltd. |

| Company 6 | Excellent | Jiangsu Aike Ruisi Packaging Automation Equipment Co., Ltd. |

| Company 6 | Excellent | Qiyang Hongtai Aluminum Co., Ltd. |

| Company 6 | Excellent | Shenzhen Weike Wind Cloud Electric Power Automation Equipment Co., Ltd. |

| Company 6 | Excellent | Guilin Shida Electromechanical Technology Engineering Co., Ltd. |

| Company 6 | Excellent | Dongguan Sigu Digital Technology Co., Ltd. |

| Company 6 | Excellent | Shandong Sanhua Li Machinery Technology Co., Ltd. |

| Company 6 | Excellent | Dongguan Xirui Automation Technology Co., Ltd. |

| Company 6 | Excellent | Tianjin Feixuan Technology R&D Co., Ltd. |

| Company 7 | Excellent | Hangzhou Dengxin Technology Co., Ltd. |

| Company 7 | Excellent | Foshan Cihui Tongda Technology Co., Ltd. |

| Company 7 | Excellent | Tianjin Haizhisheng Technology Co., Ltd. |

| Company 7 | Excellent | Ili Mulu Biological Technology Co., Ltd. |

| Company 7 | Excellent | Harbin Yixiang Innovation Technology Co., Ltd. |

| Company 7 | Excellent | Shanghai Jiaoyi Information Technology Services Co., Ltd. |

| Company 7 | Excellent | Hefei Kelly Technology Investment Co., Ltd. |

| Company 7 | Excellent | Hunan Hongyuan High Pressure Valve Co., Ltd. |

| Company 7 | Excellent | Tianjin Liuyi Agricultural Development Co., Ltd. |

| Company 8 | Excellent | Nanjing Zhongke Yuchen Laser Technology Co., Ltd. |

| Company 8 | Excellent | Zhongshan Angpa Microelectronics Technology Co., Ltd. |

| Company 8 | Excellent | Hangzhou Houda Automation Systems Co., Ltd. |

| Company 8 | Excellent | Shenzhen Saifeilu Ming Technology Co., Ltd. |

| Company 8 | Excellent | Harbin Lande Ultrasonic Equipment Co., Ltd. |

| Company 8 | Excellent | Jiangsu Huayang Heavy Industry Co., Ltd. |

| Company 8 | Excellent | Huishi (Shanghai) Measurement and Control Technology Co., Ltd. |

| Company 8 | Excellent | Zhejiang Budu Technology Co., Ltd. |

| Company 8 | Excellent | Zhuhai Yuren Flying Vehicles Co., Ltd. |

| Team 1 | Excellent | Application of New Composite Materials in Marine Engineering Equipment |

| Team 1 | Excellent | Efinix |

| Team 1 | Excellent | Bago-Robot |

| Team 1 | Excellent | Add Inc, Ltd. |

| Team 1 | Excellent | Xiamen Laisichuang |

| Team 2 | Excellent | Zhonghui Chuangzhi Wireless Power Supply Technology Dream Team |

| Team 2 | Excellent | Coast International Team |

| Team 2 | Excellent | Cai Xi Team |

| Team 2 | Excellent | Shenzhen Lei Shen Intelligent Team |

| Team 2 | Excellent | Zhiyuan Welding Team |

Excellent Enterprise Medal

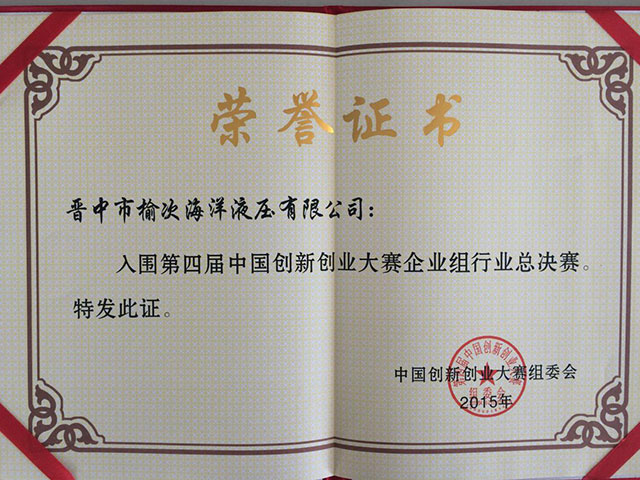

Finalist Certificate